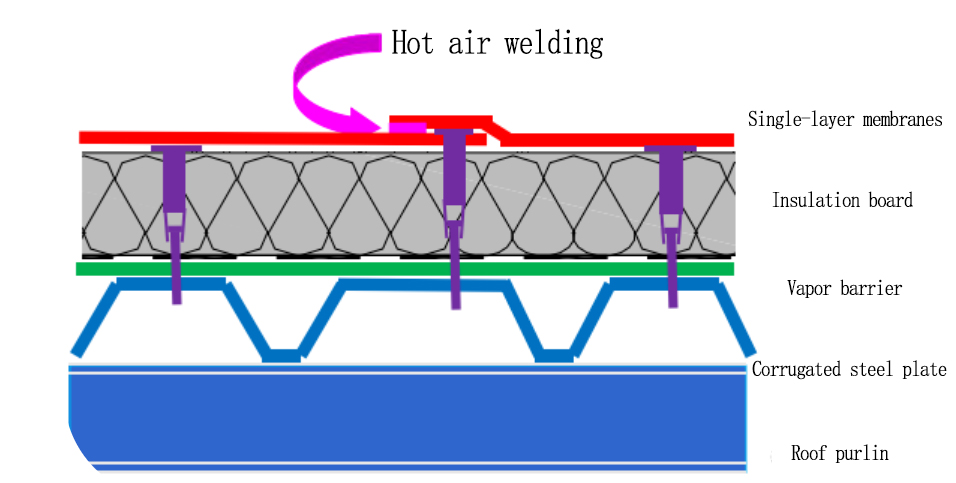

Since the factory roof structural layer is a metal plate, the large area of TPO waterproof membrane used on the factory roof can reflect most of the sunlight, effectively reduce the heat transfer of the roof, and compared with the traditional corrugated steel plate composite insulation self-waterproofing system, the waterproof effect is more prominent and is suitable for the roof enclosure of large-span buildings.

Key points of roof construction

Before construction, check the roof base to ensure that there are no obvious protrusions or depressions on the base surface. Remove debris and foreign matter to ensure that the vapor barrier is not damaged, and at the same time remove accumulated water and snow to avoid moisture hazards in the roof system in the future.

Vapor barrier construction

The vapor barrier is laid on the surface of the base according to the specifications. The overlap width of the left and right PE films is 10 cm, and the overlap direction is to overlap along the water. Use special butyl tape for bonding and sealing, and then use a roller to compact to make the upper and lower PE films firmly bonded.

Insulation layer construction

When installing the rock wool insulation board, lay it with staggered seams up and down, overlap tightly and flatly to prevent through seams, and fix it with special fixings to ensure that the insulation board has sufficient force area and reduce damage to the insulation board. The installation and covering of the rock wool insulation board should be carried out simultaneously to prevent water and moisture.

Waterproof layer construction

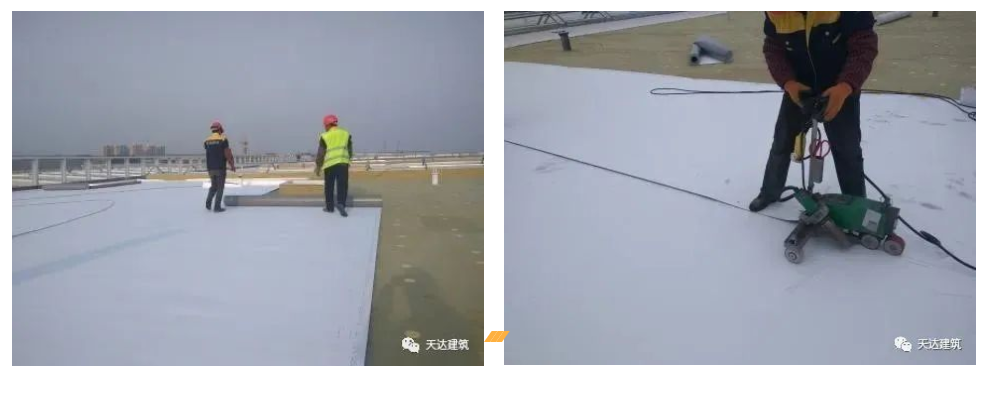

1) Membranelaying: First, pre-lay the naturally relaxed TPO waterproofing membrane on the base according to the contour line, flat and straight, without twisting, and properly cut. The laying direction of the coil should be perpendicular to the long side direction of the corrugated steel plate; the lap joints parallel to the ridge should be overlapped in the direction of the water flow, and the lap joints perpendicular to the ridge should be overlapped in the direction of the annual maximum frequency wind.

2) Membraneoverlap: The longitudinal overlap width of the coil is ≥120 mm, and it can be fixed by point or line according to the situation. For point fixation, according to the designed spacing, use a special tool to screw the fixing into the crest of the corrugated steel plate, and penetrate the steel plate by 25 mm; for line fixation, arrange the metal strips reasonably, and use an electric screwdriver to screw the fixing directly into the crest of the corrugated steel plate, and penetrate the steel plate by 25 mm.

3) Membrane welding: All overlaps of the coil are welded by hot air. Before welding, clean the welding area to remove water spots, oil stains and attachments; test the welding temperature, welding machine speed and air volume during welding, and check the weld quality after welding. The coils laid on the same day should be welded as much as possible on the same day; the interfaces left after daily construction should be protected to avoid rain and moisture.

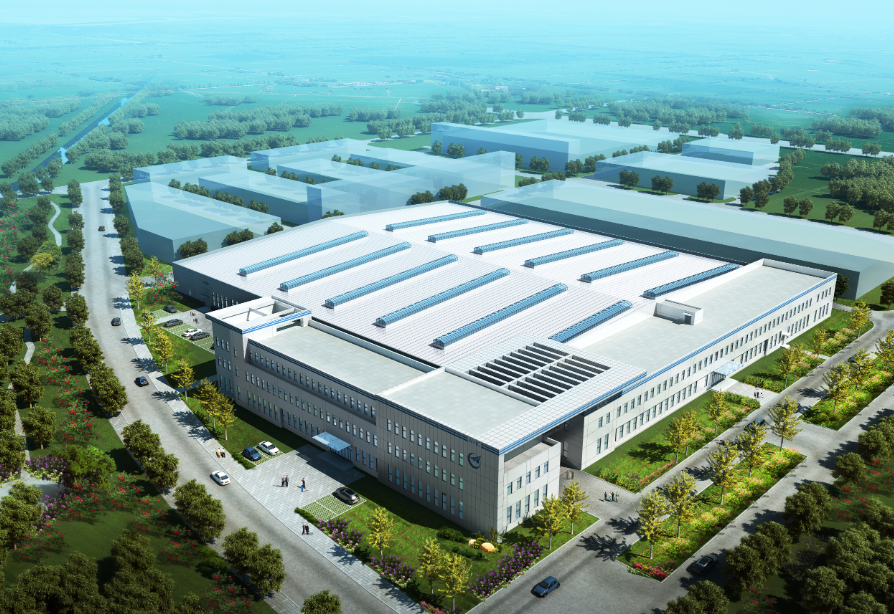

The roof of a factory building in an aviation industrial park of AVIC, which was constructed by Tianda Waterproof Building Materials Co., Ltd., uses a TPO single-layer roof system. In the design and construction of the roof system, various factors are fully considered, the construction process is standardized, and detailed nodes and construction difficulties are flexibly handled to create a leak-proof quality project. It has been three years since the project was completed, and the waterproofing and thermal insulation effects are good. It won the silver award of the "2020 Building Waterproof Industry Science and Technology Award-Engineering Technology Award (Jinyu Award)".

To know more about how the system works, how

is it installed, do get in touch with us:

+860373-2611106

jeffreyliu@lefilter.com

https://tdwaterproof.com/