Project name: Luoyang Dahehui Project

Project location: West of Longmen Highway Passenger Transport Center

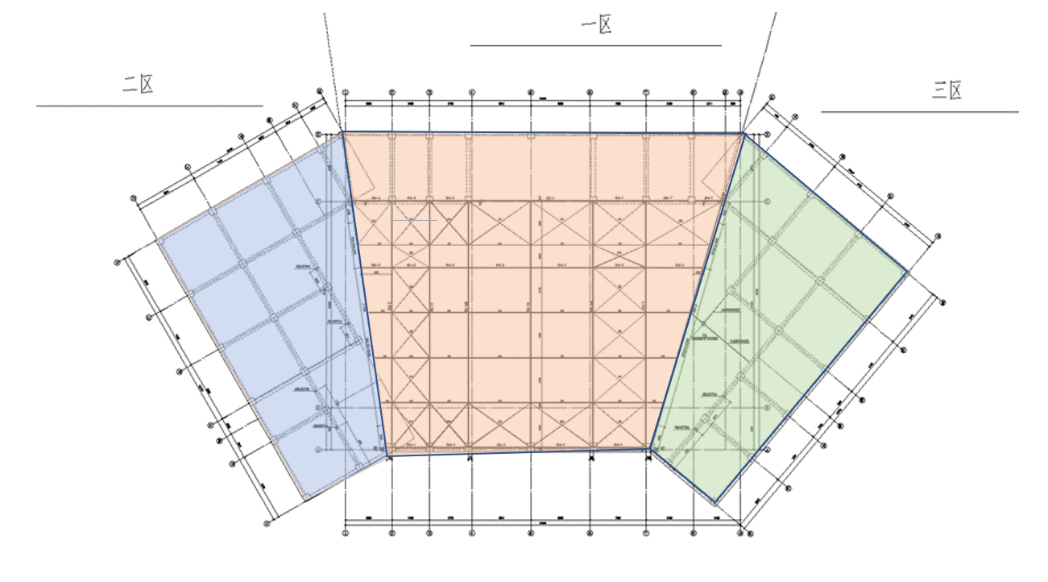

Waterproof part: Roof

Waterproof material: 1.5mm thick thermoplastic polyolefin TPO waterproof membrane

Waterproof area: about 5,000 square meters

Tianda's professional team achieves high-quality projects

The project was designed by Luoyang Machinery Design Institute No. 4. The architectural style is characterized by "ancient style with new style, Tang style with new style". The roof building form combination further highlights the Luoyang style of "mountains and rivers, rivers and mountains". Compared with other steel structures and concrete roofs, the metal roof has a beautiful and unique shape, more roof penetrations, and complex construction technology.

Tianda Waterproof Building Materials Co., Ltd, as the first and only production technology enterprise in Henan Province that focuses on polymer flexible waterproofing membranes, overcame

various construction difficulties and worked hard to make the roof waterproofing project of the project perfect. The thermoplastic polyolefin TPO

waterproofing membrane selected is cold-resistant and heat-resistant, and has a long anti-aging time, which effectively extends the service life of

the project.

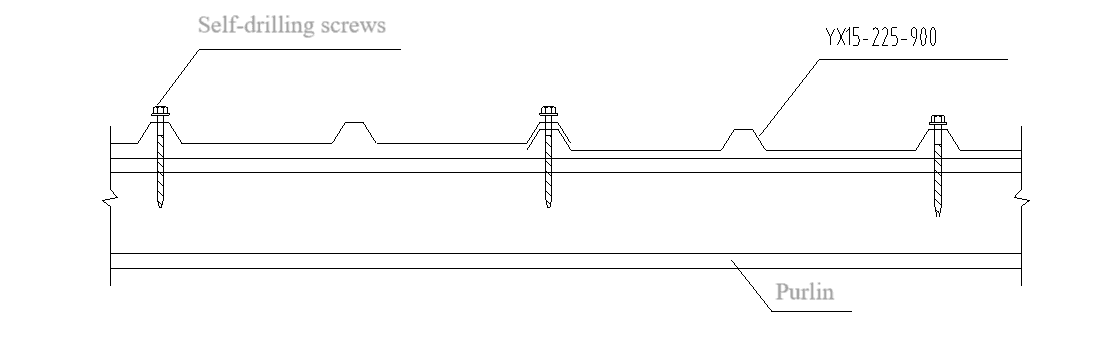

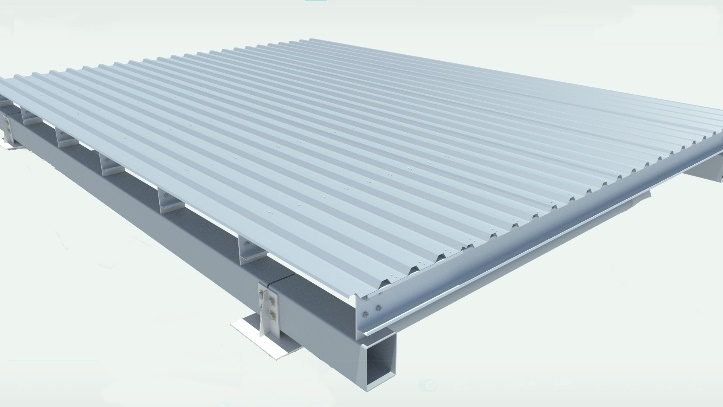

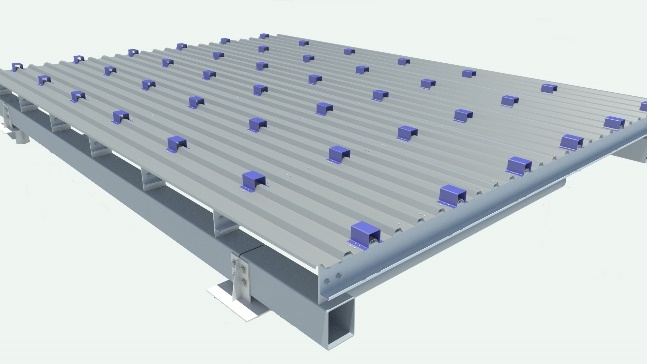

Tianda composite metal roof system structure

The metal roof adopts an aluminum-magnesium-manganese vertical lock seam roofing system. The roof is a first-level waterproof roof, and a

TPO waterproofing membrane is installed under the aluminum-magnesium-manganese metal roof. There are no exposed screws on the roof,

the entire roof is beautiful, and the hidden danger of water leakage caused by exposed screws is eliminated.

Construction technology

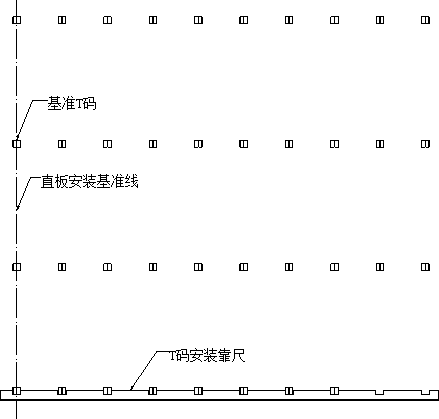

Preparing for installation

Step 1: Roof panel laying and installation

Step 2: Laying of vapor barrier membrane and installation of steady

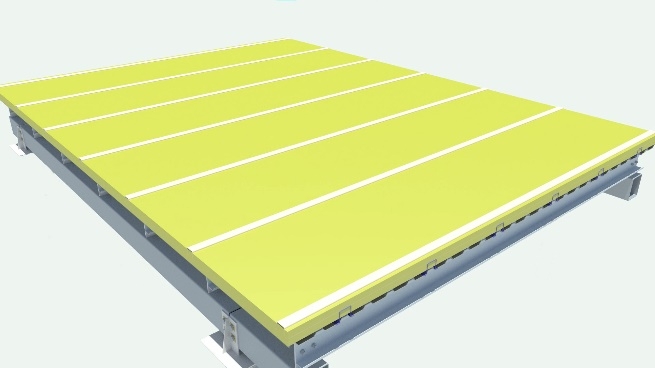

Step 3: Laying the insulation board

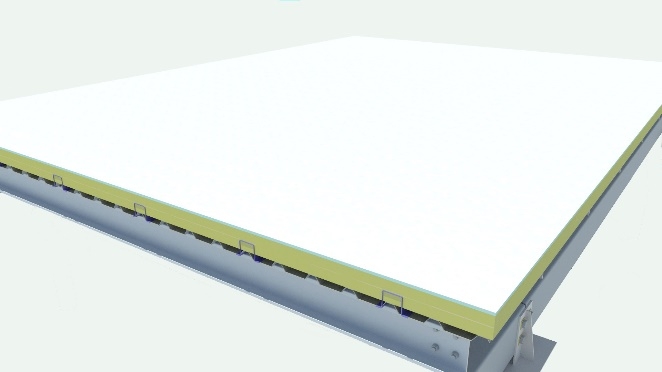

Step 4: TPO waterproof membrane construction

Step 5: Laying out and installing the aluminum-magnesium-manganese support

Step 6: On-site production of aluminum-magnesium-manganese plates

Step 7: On-site installation of aluminum, magnesium and manganese

Finished effect

Coil Finishing

Aluminum magnesium manganese plate completed

To know more about how the system works, how

is it installed, do get in touch with us:

+860373-2611106

jeffreyliu@lefilter.com

https://tdwaterproof.com/